Supplier Responsiveness vs. Communication: Key Differences

- December 9, 2025

- 17 Mins Read

- 199 Views

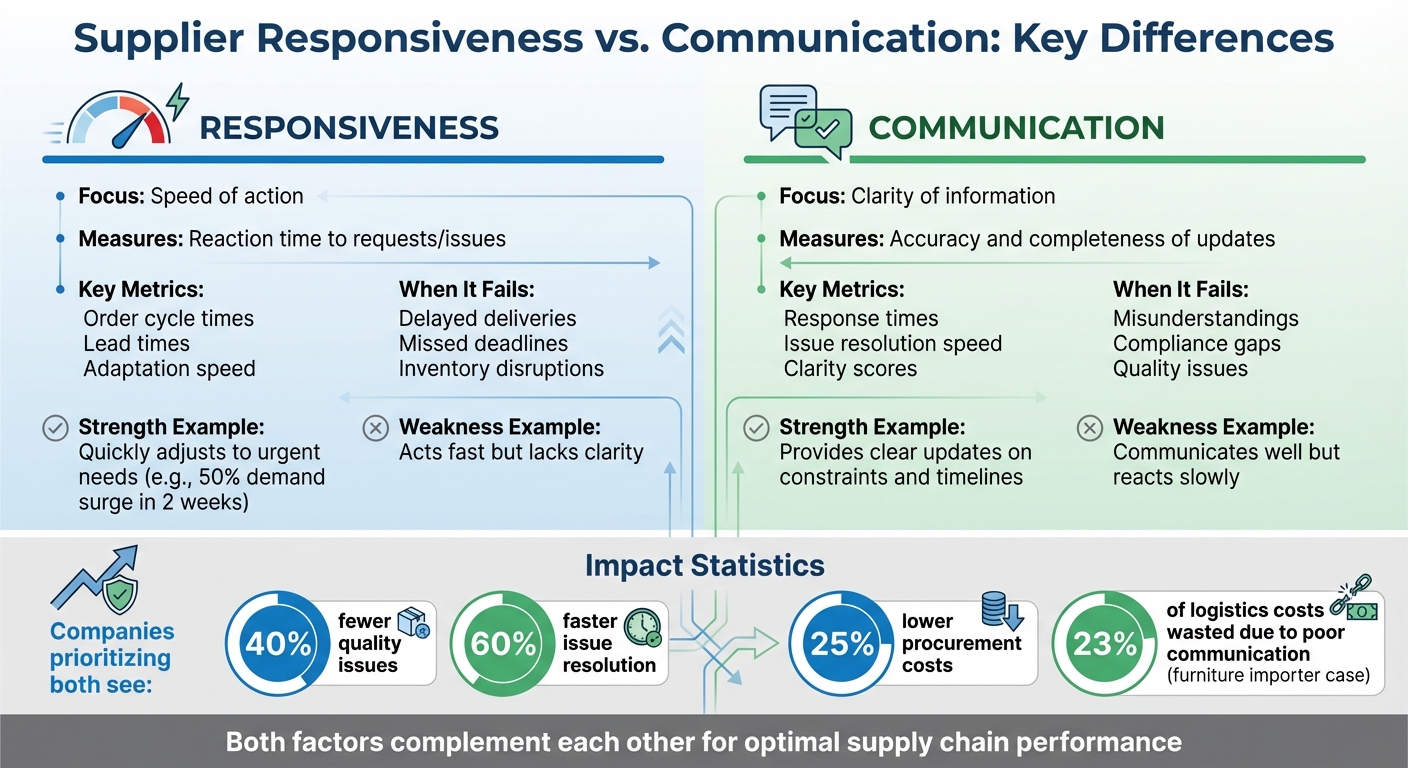

When managing suppliers, two critical factors impact your operations: responsiveness and communication. While they may seem similar, they address different aspects of supplier performance:

- Responsiveness: Measures how quickly a supplier reacts to requests, changes, or issues. It focuses on speed and agility in meeting demands, such as adjusting production schedules or resolving disruptions.

- Communication: Focuses on the clarity, accuracy, and completeness of the information shared. It ensures both parties understand expectations, risks, and updates, reducing errors and misunderstandings.

Both are essential for minimizing costs, avoiding delays, and maintaining smooth supply chain operations. For example, a supplier might respond quickly but provide incomplete details, causing errors. Conversely, clear communication without timely action can lead to missed deadlines. Balancing these two factors is key to a successful supplier relationship and improved supply chain performance.

Quick Comparison

| Aspect | Responsiveness | Communication |

|---|---|---|

| Focus | Speed of action | Clarity of information |

| Measures | Reaction time to requests/issues | Accuracy and completeness of updates |

| Failure Impact | Delays, missed deadlines | Misunderstandings, quality issues |

| Strength Example | Quickly adjusts to urgent needs | Provides clear updates on constraints |

| Weakness Example | Acts fast but lacks clarity | Communicates well but reacts slowly |

Both factors complement each other. Responsiveness ensures timely action, while communication provides the clarity needed to guide that action effectively. To improve supplier performance, track metrics like response times, issue resolution speeds, and communication clarity, and use digital tools to centralize and monitor these aspects.

Supplier Responsiveness vs Communication: Key Differences and Impact

How Can I Set Up Regular Supplier Communication?

What is Supplier Responsiveness?

Supplier responsiveness refers to a supplier’s ability to adapt quickly when faced with changes in demand, specifications, timelines, or unexpected disruptions. It’s not just about being fast – it’s about having the flexibility to adjust production schedules, reallocate resources, modify logistics, or reprioritize orders to meet evolving needs. This could involve changing order quantities, delivery dates, or shipping methods within days – or even hours – rather than weeks. In short, it’s about being nimble enough to keep up with shifting requirements.

This agility plays a crucial role in keeping supply chains running smoothly. By shortening order cycle times and reducing costly last-minute adjustments, responsive suppliers help businesses avoid bottlenecks and maintain the flow of materials, information, and cash. When disruptions occur – whether it’s a sudden surge in demand, delayed shipments, quality issues, or transportation hiccups – responsive suppliers can quickly pivot. They might re-plan production, reallocate capacity, source alternative materials, or tweak shipping methods to ensure orders stay on track. This quick action minimizes stockouts, shortens recovery times, and protects revenue and profit margins. Evaluating a supplier’s responsiveness is essential because it directly impacts operational stability and cost control.

Characteristics of Responsiveness

Suppliers known for their responsiveness tend to share several key traits:

- Speed of action: They quickly acknowledge requests, provide quotes, and implement changes, offering short lead times from order to delivery.

- Agility and flexibility: These suppliers can adjust production schedules, batch sizes, or delivery frequencies when demand shifts unexpectedly.

- Capacity for demand fluctuations: Their systems and processes allow them to scale production up or down without significant delays or quality issues.

- Proactive issue management: They notify buyers early about potential delays or shortages and often suggest alternative solutions.

- Data-driven decision-making: Using real-time insights into demand, inventory, and logistics, they can quickly reprioritize and re-plan as needed.

Examples of Supplier Responsiveness

Imagine a U.S.-based medical device manufacturer that lands a large hospital contract, requiring 50% more units within two weeks than initially planned. A responsive supplier steps up by confirming available capacity, adding an extra shift, reprioritizing less urgent orders, and arranging faster domestic transportation to meet the deadline. They also provide regular updates, helping the manufacturer adjust its production schedule and communicate accurate delivery timelines to the hospital. This avoids penalties and preserves the business relationship. Tools like QSTRAT, which streamline quoting processes and enhance visibility into supplier performance, can further support such responsiveness by reducing quote turnaround times and clarifying capacity limits.

Another scenario involves a market-wide disruption, such as a surge in demand for industrial PPE in North America. A responsive supplier might reallocate production lines, bring in qualified subcontractors, or switch to alternative raw materials to ramp up production quickly. They work closely with buyers to prioritize critical items, split shipments across locations, and use real-time data to balance supply and demand. This ensures products reach customers promptly, even during a crisis.

These examples highlight how supplier responsiveness is crucial for handling both everyday changes and unexpected challenges.

What is Supplier Communication?

Supplier communication goes beyond just the speed of responses – it’s all about the clarity, completeness, and effectiveness of the information shared between buyers and suppliers. While supplier responsiveness measures how quickly a supplier reacts, communication zeroes in on the quality of those exchanges. It ensures that both parties fully understand requirements, potential risks, changes, and decisions through agreed-upon channels. A quick response may seem helpful, but if it’s unclear, incomplete, or contradicts earlier agreements, it can create more problems than it solves.

Good communication sets the foundation for clear expectations – what will be delivered, when, how, and under what conditions. This requires precise documentation of requirements. When both sides are on the same page, the chances of misinterpreted schedules, incorrect specifications, or missed compliance requirements drop significantly. This clarity can save businesses from costly mistakes like expedited shipping fees, rework, or inventory write-offs. For instance, a furniture importer discovered that communication-related delays made up 23% of their annual logistics costs. Detailed documentation and proactive updates are key to avoiding such pitfalls.

Beyond logistics, effective communication builds trust and transparency. Suppliers who are upfront about capacity issues, lead time changes, or quality concerns allow buyers to adapt their plans before problems escalate. This open dialogue transforms supplier relationships from reactive problem-solving to proactive, collaborative partnerships that drive long-term success and resilience.

Characteristics of Communication

Suppliers with strong communication practices share a few standout traits. They flag risks early, such as production delays or quality issues, giving buyers time to adjust. They also provide consistent updates on order status, production milestones, and forecasts to maintain alignment. Standardized templates, clear subject lines, and concise summaries help reduce errors and improve clarity. Reliability is critical – information from different contacts should be consistent, with any changes clearly explained. Additionally, effective suppliers establish feedback systems, such as issue logs, formal responses to requests for information (RFIs), or post-incident reviews, to ensure clarity and enable follow-up when needed.

Examples of Effective Communication

Real-world examples show how clear communication can prevent costly disruptions. Take a U.S.-based aerospace manufacturer working with a machined parts supplier. Each week, the supplier sends a structured report summarizing completed quantities, units in quality assurance, planned shipping dates, and any schedule variances. When a critical CNC machine unexpectedly breaks down, the supplier informs the buyer within hours – not days – offering an updated recovery plan. This includes revised delivery dates and options like partial shipments, alternative production sites, or substitute materials. Such proactive communication allows the manufacturer to adjust production timelines, manage customer expectations, and avoid expensive production delays.

Another example comes from Carl Zeiss’s Strategic Sourcing team, which uses QSTRAT Sourcing during New Product Development and Engineering Change processes. The team collects over 50 data points from potential suppliers, including specifications, capacity, lead times, and compliance documentation. This detailed data exchange ensures clear expectations for trial runs, sample production, and full-scale manufacturing, reducing the risk of miscommunication.

Similarly, BAE uses QSTRAT Sourcing not just for comparing supplier costs but also as a tool to improve supplier quality. By fostering structured communication around standards and improvements, BAE turns the sourcing platform into a learning tool for its suppliers.

"For BAE, QSTRAT Sourcing is much more than a great tool to compare price, labor, raw material, packaging, and transportation among our suppliers. It’s helping BAE become a better manufacturer by using QSTRAT Sourcing as a learning tool for suppliers. Through this process we are driving our quality initiatives forward." – BAE

These examples highlight how clear, structured communication – backed by detailed documentation and the right tools – keeps buyers and suppliers aligned, reduces risks, and ensures smooth supply chain operations.

Differences Between Responsiveness and Communication

Supplier responsiveness and communication play distinct roles in supply chain management. Responsiveness is all about speed and agility – how quickly a supplier can adapt, fulfill requests, or resolve problems. On the other hand, communication revolves around clarity and transparency – how effectively information is shared and understood between parties. Think of responsiveness as the action taken, while communication is the dialogue that supports and guides that action. This difference becomes clear when comparing their metrics, impacts, and real-world outcomes.

Why does this distinction matter? Because failures in these areas create very different challenges. Poor responsiveness can lead to delayed deliveries, missed deadlines, and inventory shortages, forcing businesses to rely on costly solutions like expedited shipping, overtime, or excess safety stock. Meanwhile, poor communication results in misunderstandings about product specifications, timelines, or quality standards, which can be just as damaging.

External factors influence these capabilities differently. For example, labor shortages, natural disasters, or economic disruptions can understandably affect a supplier’s ability to respond quickly. However, these same factors shouldn’t justify poor communication. In fact, during challenging times, clear and transparent dialogue becomes even more critical to set expectations and manage uncertainties.

Comparison Table: Responsiveness vs. Communication

| Aspect | Responsiveness | Communication |

|---|---|---|

| Primary Focus | Speed and agility of action | Clarity and transparency of information |

| What It Measures | How quickly a supplier adapts and delivers | How well information is conveyed and understood |

| Key Metrics | Order cycle times, lead times, adaptation speed | Response times, issue resolution speed, clarity scores |

| When It Fails | Delayed deliveries, missed deadlines, inventory disruptions | Misunderstandings, compliance gaps, quality issues |

| External Factors | Can be hindered by uncontrollable circumstances | Can improve through better processes and technology |

| Strength Example | Supplier quickly adjusts to meet a demand surge | Supplier clearly explains constraints and provides updated timelines |

| Weakness Example | Supplier fails to adapt to urgent needs despite understanding them | Supplier acts quickly but doesn’t communicate changes effectively |

How the Two Work Together

Responsiveness and communication are not isolated concepts – they work hand in hand to build strong supplier relationships. Clear communication lays the groundwork for responsive actions. When suppliers fully understand priorities through transparent dialogue, they can act decisively without needing constant clarification. For instance, defining what qualifies as "urgent", how quality issues should be reported, and who has decision-making authority enables faster and more precise responses.

The reverse is also true. A supplier who excels in responsiveness becomes even more valuable when they pair that agility with open communication about their capabilities, constraints, and potential solutions. Companies that emphasize supplier communication report impressive results: 40% fewer quality issues, 60% faster issue resolution, and 25% lower procurement costs. For example, real-time communication systems allow manufacturers to halt production immediately when quality problems arise, enabling procurement teams to secure replacement materials quickly without waiting hours for email updates.

When responsiveness and communication are out of sync, it creates operational headaches. Imagine a supplier who rapidly begins production and expedites shipping for an urgent order but fails to provide status updates or flag potential delays. The speed is there, but the lack of transparency leads to surprises when the shipment arrives incomplete. Conversely, a supplier might deliver detailed weekly reports and proactively raise concerns about capacity limitations but still struggle to respond quickly to urgent requests due to internal bottlenecks. In this case, their communication is clear, but their responsiveness falls short. Both scenarios cause frustration and disrupt operations, highlighting the need for balance between these two capabilities. Recognizing how they complement each other is essential for evaluating suppliers and maintaining an efficient supply chain.

sbb-itb-827f251

Why Both Matter in Supplier Evaluation

Evaluating suppliers effectively means striking the right balance between speed and clarity. If you prioritize speed without clear communication, or clarity without urgency, you end up with suppliers who might act quickly but leave you guessing – or those who provide detailed information but are too slow to meet your needs. Either scenario can disrupt business performance and weaken your supply chain.

Getting this balance right isn’t just about avoiding issues – it can lead to measurable financial gains. Companies that emphasize both responsiveness and clear communication often see improvements in product quality, faster issue resolution, and lower procurement costs. On the flip side, poor responsiveness can force businesses into expensive fixes like expedited shipping, overtime labor, or maintaining large safety stock inventories.

This balance becomes even more critical during disruptions. A 2020 National Law Review study revealed that 11 out of 14 companies faced negative impacts on supplier responsiveness during the COVID-19 pandemic. Suppliers with robust communication systems were better equipped to identify problems early and manage expectations, even when external challenges slowed their response. Quick adaptability helps suppliers navigate market shifts, while clear communication ensures risks are identified and addressed before they escalate.

Beyond managing risks, this dual focus fosters collaboration and sparks innovation. Suppliers often have specialized knowledge and creative ideas that could improve your products or processes. However, without strong communication and responsiveness, these opportunities often go unnoticed or untapped.

Forward-thinking procurement teams are now making these metrics a central part of their KPIs. They track factors like order cycle times, lead time consistency, supplier response rates, issue resolution speeds, and communication clarity scores. By treating supplier communication and responsiveness as essential competencies, organizations can turn supplier management into a competitive edge – gaining access to preferred allocations during shortages, early warnings of potential risks, and valuable insights that drive innovation.

How to Assess Responsiveness and Communication in Suppliers

Responsiveness and communication are cornerstones of a strong supplier relationship, but how do you measure and improve them? To make these qualities tangible and trackable, you need a structured approach that starts during initial negotiations and continues throughout the partnership. The key lies in creating systems that make these aspects measurable and open to refinement over time.

Setting Metrics for Evaluation

To evaluate supplier responsiveness and communication effectively, integrate specific metrics into your procurement KPIs. For responsiveness, focus on measurable factors like:

- Response times: How quickly suppliers acknowledge and address requests.

- Issue resolution speeds: The time it takes to resolve problems from identification to completion.

- Order cycle times: The duration from order placement to delivery.

When it comes to communication, assess clarity by measuring:

- Completeness and accuracy: The quality of the information provided.

- Forecast accuracy: How well suppliers predict and meet demand.

- Scalability: Their ability to adjust production in response to changing needs.

Set baseline expectations during contract discussions. Define what constitutes an "urgent" request for your organization and establish clear response windows for different scenarios – for instance, 24 hours for critical issues and five business days for standard inquiries. These expectations should be documented in supplier agreements, along with details like designated points of contact, preferred communication channels, and regular check-in schedules. This upfront clarity minimizes misunderstandings and provides a benchmark for evaluating performance. Once these KPIs are in place, digital tools can help you track them efficiently.

Using Digital Tools for Monitoring

Digital platforms can simplify the process of monitoring supplier performance by consolidating communication and data in one place. Instead of juggling emails, phone calls, and scattered records, centralized systems ensure everyone operates from the same set of information, reducing errors and delays.

For example, platforms like QSTRAT streamline data management by automating notifications, validating submissions, and providing two-way communication features. These tools make it easy to track responsiveness and communication quality in real time. Automated workflows and transparent systems help you identify bottlenecks and address them promptly. Beyond tracking, these platforms also support continuous improvement by integrating feedback mechanisms.

Building Feedback Mechanisms

Feedback loops are essential for turning performance data into actionable improvements. Schedule regular performance reviews to discuss metrics like response times, issue resolution speeds, and communication clarity. These reviews provide an opportunity to highlight successes, address shortcomings, and verify critical details such as contact information and lead times.

It’s also important to consider external factors that might impact supplier performance, such as labor shortages or natural disasters. By understanding the context behind delays or lapses, you can offer constructive feedback without straining the relationship. Encourage open dialogue where suppliers feel comfortable raising concerns or suggesting improvements based on their expertise. This two-way feedback fosters collaboration and ensures both parties are aligned on goals and expectations.

Conclusion

When it comes to supply chain performance, supplier responsiveness and communication are two critical factors that must be addressed separately yet equally. Responsiveness focuses on how quickly suppliers react to requests, resolve issues, or adapt to changes. Communication, on the other hand, is about the clarity, accuracy, and consistency of the information exchanged. For example, a supplier might respond to an inquiry within two hours but provide vague or incomplete information, delaying resolution. Conversely, excellent communication without timely action can also hinder operations. Evaluating these dimensions independently helps uncover specific challenges.

The costs of poor communication and sluggish responsiveness often remain hidden but can be substantial. Take the case of a furniture importer: delays led to 23% of their annual logistics costs being spent on expedited shipping and overtime work. Ignoring these factors can drive up expenses, but prioritizing both can lead to measurable benefits – up to 40% fewer quality issues, 60% faster resolutions, and 25% lower procurement costs.

For U.S. manufacturers and distributors operating in time-sensitive markets, managing both responsiveness and communication is essential to safeguarding revenue, maintaining customer satisfaction, and optimizing working capital. Real-time communication facilitates quicker decision-making, while fast responses ensure those decisions are acted upon promptly. For instance, if a quality issue is identified upon receiving goods, coordinated communication allows teams to immediately halt production, source replacements, and reroute shipments – preventing costly delays.

To improve in these areas, integrate both responsiveness and communication metrics into supplier scorecards and performance management systems. Modern digital platforms can centralize communications, track response times, and provide real-time visibility across purchasing, quality, and logistics teams. Tools like QSTRAT simplify this process by combining sourcing, quoting, and supplier performance management into one system, enabling manufacturers and distributors to evaluate and enhance both dimensions simultaneously.

FAQs

What’s the best way to balance supplier responsiveness and communication?

To strike the right balance between supplier responsiveness and effective communication, businesses should prioritize clear and consistent communication while holding suppliers accountable for meeting deadlines and expectations. Leveraging automated tools can simplify workflows, monitor performance, and deliver real-time updates, ensuring smoother operations.

Frequent performance reviews and open, honest discussions with suppliers help establish trust and accountability. By blending actionable data with proactive communication, companies can emphasize responsiveness without compromising on clarity or teamwork.

How can you evaluate supplier responsiveness and communication effectively?

Evaluating supplier responsiveness and communication means looking at how well and how quickly a supplier handles inquiries, resolves problems, and keeps you informed with clear and consistent updates. These elements are key to ensuring smooth operations and building strong business relationships.

Here are a few important aspects to examine:

- Response time: How fast does the supplier get back to you when you send an email, make a call, or request information? Timely responses can indicate their level of attentiveness.

- Clarity of communication: Are their updates and answers straightforward, detailed, and easy to follow? Clear communication reduces misunderstandings.

- Proactivity: Does the supplier share regular updates or inform you ahead of time about potential delays or challenges? Being proactive shows they’re invested in minimizing disruptions.

Paying attention to these factors can help you assess a supplier’s dependability and their dedication to maintaining a collaborative partnership – both of which are crucial for long-term success in supply chain management.

What external factors influence supplier responsiveness and communication?

External influences can have a big impact on how suppliers communicate and respond. For example, market conditions like supply chain disruptions or raw material shortages can slow down responses or even affect the clarity and quality of communication. Another factor is time zone differences, which can be especially challenging when dealing with global suppliers. These differences might lead to delays in replies or create mismatched communication schedules.

On top of that, technological limitations can play a role. Suppliers using outdated systems or lacking automation may struggle to provide timely updates or handle inquiries effectively. Investing in modern tools and systems can help suppliers overcome these hurdles, leading to better communication and smoother operations.