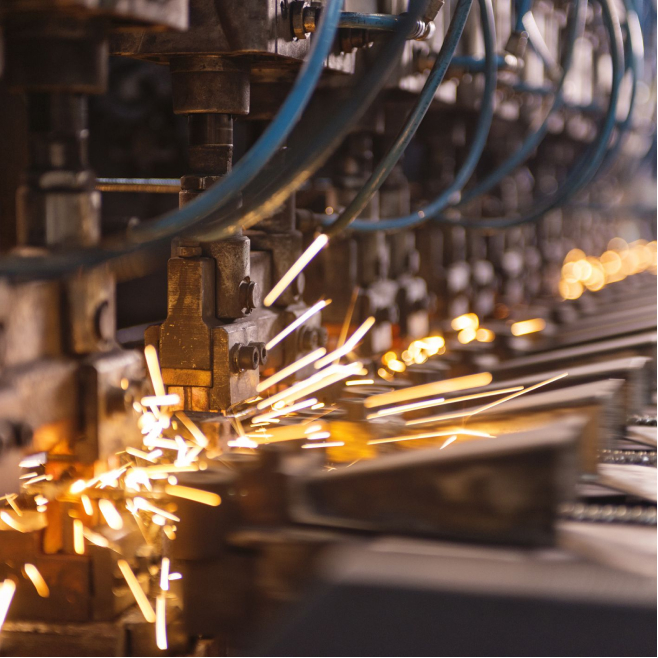

The Automotive industry faces unprecedented demand for quality, cost efficiency and new technologies.

The starting point to address these challenges is the New Product Introduction process – new programs and models.

QSTRAT supports all players in the Automotive Supply Chain in quoting and sourcing the products of the future. New product development activity has never been higher or more important.

For Tier 1 and 2 Suppliers and Distributors providing key components, QSTRAT provides the tools to quote effectively and efficiently

Business activity in the industrial sector is characterized by a relatively volatile marketplace impacted by global economic forces and longer term trends. This environment along with the scale and costs involved in many industrial projects results in a lengthy and complex quotation management process. This dynamic model translates from the OEMs to the rest of the supply chain, making an integrated system and process key to a company’s success.

Whether your company is operating as an OEM or material Supplier, the requirements to respond to a quote in this industry, and what you ask for from your suppliers continues to expand in form and content.

QSTRAT solutions provide Industrial Sector Manufacturers and Distributors the ability to:

The compliance and regulatory requirements within the Medical Device industry are at least as detailed and rigorous as they are in any industry, if not more. Whether it be FDA requirements for Process and Product validation or industry specific quality certifications, organizations working in this environment have unique and specific requirements.

These requirements for fully supported operations migrate through the supply chain, from OEM to supplier to supplier. The ability to manage these stringent requirements in an effective manner is key to an organization’s ongoing success.

QSTRAT solutions provide Medical Device Manufacturers and Distributors the ability to:

Let’s Talk

Your supply chain management processes are business-critical assets. A top trend in aerospace and defense revolves around developing a mutually beneficial relationship with suppliers.

A phenomenal article by Strategy& makes the point that “even seemingly small changes can lead to significantly improved outcomes.” Furthermore, the article draws attention to the fact that “when Aerospace manufacturers reassess and improve their interface with customers and suppliers, focus on eliminating inefficiencies and begin to alter what and how they procure, it’s not unusual to see cost reductions of as much as 30 percent.”

For Aerospace Manufacturers and Distributors, QSTRAT provides the following advantages:

Manufacturers in the electronics and high-tech industry, rely on their organization’s ability to continually innovate and then to effectively manage the changes that result.

Companies in this marketplace are faced with constant pressure on margins from customers as well as suppliers, while working within dynamic global supply chains. Material availability, unique challenges with international shipments and other uncontrolled factors are all cost elements often out of one’s control. Managing this variety of challenges must also be completed in an age of increasingly stringent standards and industry regulations.

QSTRAT solutions provide Electronics and High-Tech Manufacturers and Distributors the ability to:

Deployments are tailored to your organizational needs.

QSTRAT offers on-demand, on-premise or hybrid

deployment options.

QSTRAT, a leading innovator in software solutions, is excited to announce the launch of its revamped user interface (UI), designed to enhance the user experience and significantly improve the efficiency […]

Please fill out the form and a QSTRAT

representative will get back to you shortly.