A quoting library is a centralized system that organizes essential data like material costs, labor rates, and process templates to streamline and standardize pricing in high-tech manufacturing. It replaces scattered spreadsheets and outdated methods, cutting quote preparation times significantly – from hours or days to just minutes for simple components. This system is critical for industries like aerospace, medical devices, and electronics, where complex BOMs, strict regulations, and fluctuating costs demand precision.

Key Points:

- What it does: Centralizes material, labor, and process data for consistent and accurate quotes.

- Why it matters: Ensures compliance, improves efficiency, and reduces risks in complex industries.

- How it works: Tools like QSTRAT integrate with ERP/CRM systems to automate updates, manage supplier data, and enforce consistent quoting practices globally.

Setting Scope and Standards for Your Quoting Library

Determining Scope for High-Tech Manufacturing Quotes

When building a quoting library for high-tech manufacturing, it’s important to define its scope across four key dimensions: business scenario, product/service coverage, regions/currencies, and customer segments.

Start by distinguishing between prototype/New Product Introduction (NPI) quotes and full-production quotes. Prototype or NPI quotes typically involve low volumes, quick turnarounds, and exploratory pricing, while full-production quotes include volume breaks, tooling amortization, and long-term agreements. Many high-tech companies initially focus on production quotes for their top 100 SKUs before expanding to prototypes once their standards are well-established.

For product coverage, identify which product families generate the most RFQs (Request for Quotes). Examples might include PCB assemblies, semiconductor devices, machined housings, cable assemblies, or test fixtures. Prioritize high-volume or high-margin lines to maximize efficiency.

Regional considerations are also critical. Decide which manufacturing locations and currencies your library will support. For example, U.S.-based plants quoting in USD need to account for regional labor rates, overhead costs, and logistics. Global operations, on the other hand, require support for multiple currencies and location-specific cost drivers. Additionally, consider whether different customer segments – like aerospace, medical devices, telecom, or data centers – need unique quote templates due to varying compliance, documentation, or service-level requirements.

A great example of this approach is Carl Zeiss. Their Strategic Sourcing team uses QSTRAT Sourcing to gather over 50 data elements from qualified suppliers during New Product Development and Engineering Change processes. This structured data collection supports trial runs, sample production, and eventually full production volumes. By defining the scope clearly, they ensure their quoting library meets the needs of both new product introductions and ongoing business.

Once the scope is clear, the next step is to implement controls to maintain consistency.

Creating Governance and Approval Processes

Without proper governance, quoting can become inconsistent and error-prone. A role-based governance model is essential to keep things organized. For example:

- Quote owners and sales engineers: Handle individual quotes but don’t modify master cost libraries or templates.

- Costing and manufacturing engineers: Manage process routings, cycle times, machine rates, and manufacturing assumptions.

- Commercial and finance teams: Oversee price lists, discount policies, margin targets, and surcharges.

- Compliance and quality teams: Approve regulatory profiles and changes affecting standards such as AS9100, ISO 13485, or ITAR.

Approval thresholds should be based on financial value and risk. For instance:

- Quotes up to $50,000 might be approved by a sales manager.

- Quotes between $50,000 and $250,000 could require approval from a regional director.

- Quotes over $250,000 might need a VP or executive committee’s sign-off.

Additional approvals should be triggered when gross margins fall below standard levels or when discounts exceed set limits, such as more than 10% below list price. For specialized industries like aerospace or medical devices, quotes involving ITAR-controlled work, safety-critical components, or regulated materials should automatically route to compliance and quality reviews.

Tools like QSTRAT automate requisitions, notifications, and approvals, ensuring consistent engagement from stakeholders without creating unnecessary delays.

Setting Up Data Standards for High-Tech Manufacturing

With scope and governance in place, the focus shifts to establishing robust data standards. Start with a part numbering scheme that encodes key details like product family, material category, technology, and revision. For instance, separate codes might identify semiconductor wafers, PCBAs, mechanical housings, cables, and test fixtures. Avoid overly complex coding systems to keep things manageable.

Define standardized product families and subfamilies. For example:

- "PCBA > High-density SMT > BGA-intensive"

- "Machined > Aluminum > 5-axis"

Standardized families allow for reusable cost drivers and routing templates. Attach normalized attributes to each part, such as layer count, board size (in inches), tolerance ranges, surface finish, cleanliness class, operating temperature (in °F), and compliance statuses like RoHS or REACH. Use controlled vocabularies and stick to U.S. units (inches, mils, °F, lbs) for consistency.

Revision control is another critical aspect. Assign version numbers (e.g., v1.2) to quote templates, routing templates, and cost models, along with effective dates and change rationales. Require formal reviews and approvals before publishing new versions and assess their impact on open quotes and key customers. Archive data sets used for released quotes – covering materials, labor rates, overhead, and risk premiums – to ensure traceability during audits, particularly in regulated industries like aerospace or medical devices.

Finally, ensure every quote includes mandatory attributes such as:

- Currency (USD)

- Unit of measure

- Incoterms

- Payment terms

- Quote validity period

- Minimum order quantity

- Price break structure

- Manufacturing process

- Material grade/specifications

- Quantity bands

- Lead-time tiers (expedite, standard, economy)

- Finishes and post-processing details

- Inspection/documentation levels (e.g., standard inspection, FAI, 100% CMM, material certifications)

- Compliance flags (e.g., ITAR, EAR, RoHS, REACH, ISO 13485, AS9100)

These standards ensure that every quote is complete, comparable, and ready for audit.

Organizing Your Quoting Library for High-Tech Parts and Processes

Creating Reusable Components for Materials and Processes

A well-organized quoting library begins with reusable components that estimators can easily integrate into quotes. These components should build upon the data standards and scope you’ve already established.

Start by categorizing material families specific to your high-tech sectors. For instance, in PCB assemblies, create reusable material records for laminates like FR‑4, high‑Tg, Rogers RF/microwave substrates, and polyimide flex. Each record should include details like thickness options, copper weights (e.g., 0.5 oz, 1 oz, 2 oz), dielectric properties, and panel utilization guidelines. For precision machining, standardize materials such as specialty steels (e.g., 17‑4 PH stainless and Inconel 718), aluminum alloys (e.g., 6061‑T6 and 7075‑T6), titanium (Ti‑6Al‑4V), and engineered plastics like PEEK and Ultem. Capture machinability ratings, typical stock forms (bar, plate, or billet), and other critical data. For medical and defense applications, include biocompatible alloys (e.g., Ti‑6Al‑4V ELI), implant-grade PEEK, and materials subject to DFARS/ITAR or country-of-origin restrictions. Each material should list its USD price, typical yields, scrap rates, density, and approved suppliers.

Next, create process templates that combine technical parameters with cost logic. For example, a CNC machining template might detail machine class (3‑axis or 5‑axis), tolerance levels (±0.005″ or ±0.001″), surface finish ranges (125 Ra or 32 Ra), tool change allowances, setup times, and cycle times – all linked to machine and labor rates. Similarly, an SMT assembly template could document line configurations, feeder setup times, placement speeds for different component types (e.g., 0402 passives, QFN packages, BGA), solder paste options, and reflow profiles. Cleanroom assembly templates might include ISO class requirements, gowning times, overhead costs, and lot sizes. These templates should be tied to specific part types, like "Class III medical PCB assembly" or "aerospace precision-milled bracket", so new quotes can automatically inherit proven time and cost relationships.

To keep everything manageable, organize your library hierarchically in a way that aligns with how engineers and estimators think. At the top level, separate by product family – PCB assemblies, cable harnesses, machined components, and microelectronics modules. Under each family, create subfolders for materials (e.g., metals, plastics, adhesives), processes (fabrication, assembly, testing), and compliance (documentation, certifications). Further segment processes into specific operations like milling, turning, SMT assembly, and conformal coating. Use consistent naming conventions, such as "PROC_SMT_STD_CLASS2" or "MAT_FR4_HIGH_TG_1.6MM", to ensure components remain easy to find and identify as the library grows.

This modular structure can also include regulatory and testing components to address compliance needs.

Adding Regulatory and Testing Elements

For industries like aerospace, medical devices, and defense, strict quality and compliance standards are a given. Your quoting library should treat these requirements as dedicated cost objects that can be attached to quotes based on the industry, customer, or part’s criticality.

For aerospace, define FAIR (First Article Inspection Report) components that include engineering reviews, CMM inspections, and reporting. These might be structured as a one-time non-recurring expense (NRE) plus a per-lot charge. Automotive applications could include PPAP levels (1 through 5), each specifying documentation needs, validation tasks, lab tests, and approval cycles. Medical devices might require components for DMR/DHR creation, design validation, sterilization validation, and ongoing lot-release recordkeeping. Each regulatory component should estimate the hours required (broken down by roles like quality engineer or inspector), lab/test fees, and whether costs are spread across production volume.

Testing activities can also be standardized. For example, an AOI (Automated Optical Inspection) template might detail setup times by board family, scan times per square inch, and handling requirements for double-sided boards. An ICT (In-Circuit Test) template could include fixture development costs, node/probe counts, debug hours, and per-board run times. Functional tests should account for software load times, script development, per-unit run times, and any specialized operator skills required. For environmental tests like burn-in or temperature cycling, include factors like chamber utilization rates, test durations, fixture density, and energy costs.

Many advanced quoting platforms allow users to specify certifications and inspection needs – like CMM reports or First Article Inspections – directly in the quote configuration. This makes it easier to standardize quality and regulatory tasks as reusable components, ensuring estimators can include compliance details consistently without starting from scratch.

With these reusable components in place, QSTRAT simplifies library management and ensures consistency in quoting practices.

Using QSTRAT to Organize Your Quoting Library

QSTRAT centralizes your quoting library, creating master records for materials, processes, and compliance that feed directly into standardized RFQ and quote templates. Its hierarchical organization system allows you to structure records by product family, operation type, and region. Regional variations – such as labor rates, material costs, or preferred suppliers – can be managed through location-specific overrides while maintaining the same master logic.

QSTRAT integrates seamlessly with ERP, costing, and sourcing systems, keeping your library synchronized with the latest supplier data and performance metrics. This reduces manual updates and ensures accurate cost drivers for both domestic and global quoting.

BAE Systems uses QSTRAT Sourcing to standardize cost components – such as price, labor, raw materials, packaging, and transportation – across suppliers. These elements are treated as reusable building blocks for defining and evaluating manufacturing processes. As BAE Systems explains:

"For BAE, QSTRAT Sourcing is much more than a great tool to compare price, labor, raw material, packaging, and transportation among our suppliers. It’s helping BAE become a better manufacturer by using QSTRAT Sourcing as a learning tool for suppliers. Through this process we are driving our quality initiatives forward."

To keep your library organized as it grows, establish clear ownership and change control. Assign a dedicated team, such as cost engineering or operations, to oversee the library and approve new materials, processes, and compliance components. Implement a structured process for adding or updating entries, including justification, verified data sources (like supplier quotes or regulatory updates), and impact assessments. Schedule regular reviews – quarterly for high-impact categories like key materials and labor rates – and use versioning to ensure historical quotes remain traceable to their original logic. Finally, enforce mandatory fields and consistent naming conventions to prevent incomplete or duplicate entries.

Identifying and Standardizing Cost Drivers

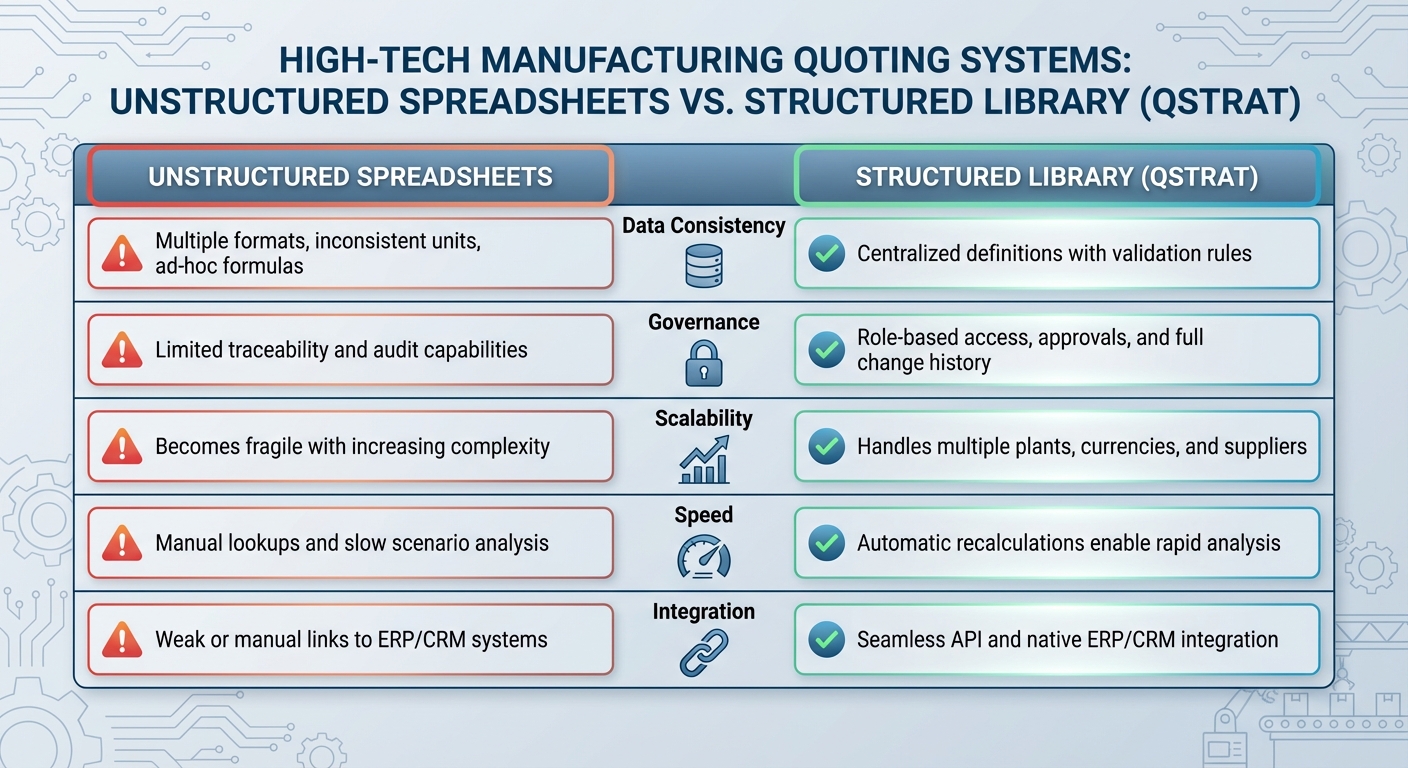

Spreadsheets vs Structured Quoting Library Comparison for Manufacturing

Once your quoting library is well-organized, the next step is to define precise cost drivers. This process enhances pricing accuracy by ensuring each quote reflects the actual, current costs of manufacturing.

Common Cost Drivers in High-Tech Manufacturing

In high-tech manufacturing, cost drivers typically fall into two categories: feature-based and process-based.

- Feature-based drivers stem from design elements, such as microvia count, hole density, and fine-pitch components. These features can impact cycle times, tool wear, scrap rates, and inspection needs. For instance, a design with dense microvias might require additional drilling steps, specialized tools, and more time for automated optical inspection (AOI), compared to a simpler design.

- Process-based drivers are tied to manufacturing workflows. These include factors like machine setup time, changeover durations, run rates (e.g., SMT placement speeds or CNC feed rates), yields, scrap percentages, and inspection intensity (e.g., AOI scans or burn-in hours). Regulatory requirements, such as AS9100 documentation or IQ/OQ/PQ validation, also fall under this category. These drivers are often modeled as hourly labor or machine costs, percentage-based yield assumptions, or fixed charges per lot, which are then factored into unit cost calculations based on batch sizes and expected yields.

Regulatory and compliance-related drivers should also be accounted for as labor or machine costs, fixed charges, or percentage-based adjustments.

Standardizing and Organizing Cost Data

To streamline cost data, normalize information from various sources into a single, consistent format. For example, consolidate all "setup time" entries into one standardized field, such as "Machine_Setup_Time_HR." Use uniform units – like inches for dimensions, pounds for weight, hours for time, and USD for currency – and document the dates of conversions for reference. Clear naming conventions, such as PCB_Microvia_Count_EA or CNC_Setup_Time_HR, help ensure consistency. Prefixes like PCB_, CNC_, SMT_, or TEST_ can group related data by discipline.

Decimal precision should align with the sensitivity of each driver. For example, critical dimensions might require precision to 0.0001 inches, while labor hours can be rounded to 0.01. Maintain a master list of materials, machines, and routings to avoid duplicate entries, and use range checks (e.g., flagging labor rates under $10/hour or yields above 99.99%) to identify and resolve anomalies with input from engineering and finance teams.

QSTRAT simplifies this process by offering structured import templates (e.g., CSV or Excel files with predefined columns for driver IDs, descriptions, units, rates, effective dates, and plant tags). It also supports API integration with ERP, PLM, and CRM systems, ensuring continuous data synchronization. Administrators can manage tables for labor rates, machine costs, materials, and overheads, linking these directly to quoting rules. This ensures that updates automatically reflect in new quotes while preserving historical versions. Role-based workflows enhance governance by requiring engineering to propose changes, finance to validate them, and designated owners to approve before implementation.

This structured approach provides a strong foundation for the benefits discussed below.

Benefits of a Standardized Cost Driver Library

A centralized library offers significant advantages over ad-hoc spreadsheets. While spreadsheets often suffer from inconsistent units, ad-hoc formulas, and limited traceability, a structured system enforces uniform definitions, validation rules, and version control. This ensures better compliance and easier audits.

Scalability is another key advantage. As the number of products, plants, currencies, and suppliers grows, spreadsheets become increasingly fragile. Systems like QSTRAT, on the other hand, are built to handle multiple locations, currencies (including USD), and supplier price lists within a single master library. Rules-based costing allows for automatic recalculations when drivers are updated, enabling quick scenario analyses – such as comparing lot sizes, alternate materials, or manufacturing locations. Integration with ERP and CRM systems eliminates duplicate data entry, ensuring alignment between quoting, production, and financial processes.

| Aspect | Unstructured Spreadsheets | Structured Library (QSTRAT) |

|---|---|---|

| Data consistency | Multiple formats, inconsistent units, ad-hoc formulas. | Centralized definitions with validation rules. |

| Governance | Limited traceability and audit capabilities. | Role-based access, approvals, and full change history. |

| Scalability | Becomes fragile with increasing complexity. | Handles multiple plants, currencies, and suppliers. |

| Speed | Manual lookups and slow scenario analysis. | Automatic recalculations enable rapid analysis. |

| Integration | Weak or manual links to ERP/CRM systems. | Seamless API and native ERP/CRM integration. |

For example, the Strategic Sourcing team at Carl Zeiss uses QSTRAT Sourcing to gather over 50 data points from qualified suppliers during bidding. This structured approach supports trial runs and sample production, eventually leading to full-scale manufacturing. Similarly, BAE uses QSTRAT to compare cost components – like price, labor, raw materials, packaging, and transportation – across suppliers. This helps drive quality improvements while keeping costs in check.

sbb-itb-827f251

Updating and Improving Your Quoting Library

Keeping your quoting library current is crucial for maintaining accuracy and staying compliant as markets and regulations change. Fluctuating material costs, market dynamics, and engineering updates all demand regular attention. To ensure your quotes stay reliable, implement a structured maintenance schedule that outlines who is responsible for updates and how frequently they occur. For high-tech manufacturing, this might mean quarterly reviews of labor rates and standard routings, monthly or bi-monthly updates for key material costs (like metals, resins, or semiconductors), and semiannual checks for overhead absorption rates and target margins. Regulatory and certification elements should be reviewed annually or whenever new standards or customer-specific requirements arise. A disciplined schedule is key in this ever-changing environment.

Regular Maintenance and Updates

Assign clear responsibilities for managing different parts of the library. For example:

- Finance typically oversees labor rates, overhead multipliers, and margin rules. These are often expressed in USD (e.g., $38.50/hour for standard labor).

- Purchasing handles raw material pricing and subcontractor costs, pulling data from ERP systems or supplier contracts.

- Engineering maintains routings, cycle times, and machine capabilities, updating them with engineering change orders (ECOs) or when new equipment is introduced.

- Quality or Regulatory Teams manage compliance-related costs, such as first article inspections (FAI), validation testing, and documentation.

To streamline updates, integrate your quoting library with ERP, HR, and purchasing systems using APIs or scheduled imports. This automation reduces manual data entry and ensures sales and estimating teams always have access to the latest information. For instance, if a supplier changes the cost of a specialty alloy, that update should automatically reflect in all relevant quotes without requiring manual adjustments to spreadsheets or templates.

Auditing and Compliance for High-Tech Manufacturing

In industries like aerospace and medical devices, the quoting library needs to function as a controlled asset. This means keeping versioned records of rate tables, cost models, and templates – such as "LaborRates_v2026.1" – with clear start and end dates. Editing rights should be restricted to authorized personnel, and any changes to margin rules or cost models should require dual electronic approvals. Maintain a non-editable history log that records every change, including the old value, new value, user ID, timestamp, and reason for the update.

Each quote should also be archived with its corresponding library versions to ensure traceability. This allows you to recreate the pricing logic used at the time, even if the library has since been updated. For contracts requiring re-pricing, create a new revision of the quote (e.g., Quote 14523 Rev B) tied to the updated library versions. Tools like QSTRAT support controlled workflows, access permissions, and audit logging, which simplify compliance and traceability during ISO, FDA, or customer audits. Insights from these audits can also help refine your quoting models.

Using Performance Data for Improvement

Compare your quoted costs with actual job costs at the line-item level, and flag any variances beyond ±5%. Use these discrepancies to fine-tune cost assumptions, such as cycle times, scrap rates, or setup allowances, especially if you notice consistent over- or underestimations. For example, one QSTRAT client shared:

"By leveraging QSTRAT’s suite of products with our existing MFG/PRO and Cyberquery solutions, we can now accurately quote, track successes, and measure the accuracy of our projected costs versus our actual costs when entered into our MFG/PRO system."

Set up dashboards in QSTRAT or your CPQ system to monitor key metrics like win rates by product line and price band, average quote cycle time, and margin variance trends. These insights can guide updates to your quoting library, helping you refine your pricing strategy and maintain a competitive edge.

Conclusion

A well-organized quoting library can transform high-tech manufacturing by delivering fast, accurate pricing that accounts for real costs, current regulations, and supplier capabilities – all typically within 24–48 hours. The benefits are clear: quicker responses, improved win rates, better margin control, and the ability to grow without relying solely on a few senior estimators.

QSTRAT enhances your team’s expertise rather than replacing it. The platform captures the knowledge of your engineers, cost estimators, and sourcing professionals, ensuring consistency by applying standardized templates, cost drivers, and supplier data across thousands of quotes. By syncing with your ERP, CRM, and costing systems, QSTRAT automates routine tasks like retrieving up-to-date material prices (in USD), labor costs, and supplier performance metrics. This automation lets your experts focus on higher-value activities like design-for-cost strategies, supplier planning, and complex negotiations. The seamless integration creates a quoting system that evolves alongside your business.

Think of your quoting library as a living system. Regularly reviewing cost drivers, analyzing feedback from both successful and lost bids, and auditing data quality are essential to keeping your quotes competitive as material costs change and customer needs shift.

Start small: focus on one high-value product family, assign clear responsibilities, and set measurable goals for accuracy and turnaround time. Tools like QSTRAT can help digitize your library, streamline global sourcing, and embed best practices into your processes. Over time, the insights gained from quoting and sourcing data will refine your cost models, align strategy with execution, and keep you competitive in a market where speed, accuracy, and compliance are critical. By building on standardized processes and committing to continuous improvement, your quoting library can meet today’s needs while adapting to tomorrow’s challenges.

FAQs

How can a quoting library enhance pricing accuracy in high-tech manufacturing?

A quoting library plays a key role in improving pricing precision within high-tech manufacturing. By organizing and standardizing essential data, it minimizes the chance of manual errors and ensures consistent, reliable cost estimates tailored to the intricate demands of manufacturing.

With real-time, detailed data at their fingertips, manufacturers can make smarter decisions, simplify their quoting process, and stay competitive in an industry where speed and accuracy are crucial.

What essential elements should a quoting library include for aerospace or medical device manufacturing?

When creating a quoting library for industries like aerospace or medical device manufacturing, it’s essential to include several key elements. Start with detailed technical specifications, compliance and regulatory requirements, and material and component data. These ensure that the quotes align with the precise needs of the project and adhere to strict industry guidelines.

You’ll also want to factor in manufacturing tolerances, cost breakdowns, and lead times. Together, these details help provide accurate quotes while keeping production timelines and budgets in check.

To further refine the quoting process, include supplier performance metrics, quality assurance criteria, and historical quote data. These components not only enhance accuracy but also support consistency and compliance with industry standards, making the entire process more reliable and efficient.

How does QSTRAT simplify maintaining and updating a quoting library for high-tech manufacturing?

QSTRAT makes managing your quoting library easier by automating essential tasks and integrating data effortlessly. It allows you to update quotes quickly, ensuring your library remains accurate and consistent.

By incorporating real-time data and supplier inputs, QSTRAT keeps your quoting library current, enhances communication with stakeholders, and helps monitor supplier performance. This efficient system lets you create and adjust customer quotes seamlessly, meeting the demands of high-tech manufacturing with ease.