Global supplier sourcing is about finding and working with suppliers worldwide to meet manufacturing needs. It goes beyond cutting costs – it’s about accessing specialized skills, advanced technologies, and unique materials unavailable locally. This approach helps companies diversify risks, improve supply chain reliability, and stay competitive.

Key takeaways:

- Why it matters: Access specialized expertise (e.g., precision machining in Germany, electronics in Asia) and build a resilient supply chain.

- Digital tools: Cloud platforms now streamline supplier management with real-time data sharing, automated workflows, and compliance tracking.

- Process overview: Identify suppliers, evaluate and select them, negotiate contracts, and manage relationships effectively.

- Risk management: Mitigate risks like supplier bankruptcy or delivery delays through diversification, financial assessments, and performance monitoring.

- Compliance and cost: Stay on top of regulations (e.g., ITAR, CE marking) while optimizing costs through total cost analysis and supplier development programs.

This guide explains how to build strong global supplier partnerships, manage risks, and use digital tools to improve sourcing efficiency.

GLOBAL SOURCING GUIDE: Revealing the Complex World of International Procurement with David Alexander

Key Stages of the Global Sourcing Process

Global sourcing involves a step-by-step approach that turns initial requirements into strong, reliable partnerships with international suppliers. Each phase builds upon the previous one to establish a solid foundation for successful collaboration. Thanks to modern cloud-based platforms, these processes have become far more streamlined and efficient.

Supplier Identification

This phase begins by defining clear requirements and conducting a thorough search of global supplier databases. With the help of digital supplier directories, industry networks, and cloud-based tools, companies can now access a broader pool of potential partners. These platforms often provide detailed profiles, including certifications, capabilities, and other essential data.

Key criteria for selecting suppliers include certifications like ISO 9001, AS9100 for aerospace, or ISO 13485 for medical devices. Suppliers must also demonstrate the capacity to meet production volumes without sacrificing quality or delivery timelines. Location is another critical factor, as it impacts shipping costs, lead times, and potential supply chain risks.

Platforms like QSTRAT simplify this process by allowing procurement teams to filter suppliers based on factors like industry, certifications, and geographic location. They also integrate performance data, helping teams identify suppliers with proven track records. Additionally, assessing financial stability is crucial to ensure suppliers can handle long-term commitments and invest in improvements. Many platforms now include financial health indicators and risk assessments to aid in this evaluation.

Supplier Evaluation and Selection

Once potential suppliers are identified, the next step is a detailed evaluation. This includes cost analysis, quality assurance reviews, compliance checks, and sometimes even on-site audits. The goal is to determine how well each supplier aligns with the project’s specific needs.

Cost analysis goes beyond unit prices to include factors like shipping, duties, and quality control expenses. Manufacturers also account for risks like currency fluctuations and potential tariff changes when considering international suppliers.

Quality assurance involves reviewing the supplier’s quality management systems, testing processes, and defect rates. For industries with strict regulations, ensuring compliance is a critical part of the evaluation. Tools like QSTRAT offer built-in templates and scoring systems to standardize these assessments, making it easier for teams to collaborate and provide transparent input.

After completing evaluations, the focus shifts to negotiations aimed at creating clear and mutually beneficial agreements.

Negotiation and Contracting

Negotiating with international suppliers requires clear communication and an understanding of cultural and legal differences. The process starts by defining expectations around pricing, quality standards, delivery schedules, payment terms, and performance metrics. The goal is to establish a partnership that benefits both parties, rather than focusing solely on cost-cutting.

Contracts must address key elements such as currency risks, Incoterms, and dispute resolution mechanisms. Digital contract management tools play a vital role here, offering features like version control, electronic signatures, and automated reminders for renewals. QSTRAT’s contract management module includes approval workflows to ensure all terms are reviewed and agreed upon by stakeholders. It also provides a library of contract templates to streamline future agreements.

Payment terms – whether through letters of credit, escrow, or milestone-based payments – are structured to minimize risk. Contracts should also clearly define intellectual property ownership, which is particularly important given the varying international IP laws.

Once agreements are finalized, maintaining the relationship becomes the next critical focus.

Supplier Relationship Management

Building and sustaining supplier relationships requires more than just a contract. It involves continuous monitoring, open communication, and collaborative problem-solving. Over time, the best relationships evolve into strategic partnerships that drive mutual growth and innovation.

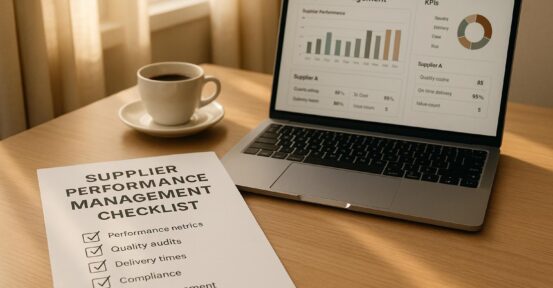

Performance monitoring is key, with metrics like on-time delivery, quality standards, and responsiveness being closely tracked. Cloud-based platforms now offer real-time dashboards that give procurement teams instant insights into supplier performance, allowing them to address issues before they escalate.

Regular communication is equally important, especially when managing across time zones. Structured protocols, such as scheduled review meetings and performance discussions, help maintain alignment and address challenges quickly. Cloud-based collaboration tools make this process smoother and more consistent.

When problems arise, having clear escalation procedures and response timelines is crucial. Many successful partnerships treat challenges as opportunities to improve rather than sources of conflict. Joint initiatives, such as process improvements or technology sharing, can further optimize operations and reduce costs for both parties. Tools like QSTRAT support these efforts by integrating communication features, performance tracking, and data-driven decision-making tools to enhance long-term supplier relationships.

Using Cloud-Based Sourcing Platforms

Cloud-based sourcing platforms are changing the way global supplier management works. These tools break down geographic and communication barriers, allowing procurement teams to make quicker and smarter decisions while keeping a clear view of their entire supply chain. By centralizing data and automating key processes, these platforms ensure smoother operations and better collaboration.

Core Benefits of Cloud-Based Tools

Centralized data access eliminates the need for scattered spreadsheets. Stakeholders get consistent access to supplier profiles and performance metrics, ensuring everyone is working with the same, accurate information. This approach removes data silos and improves team alignment.

Automated workflows handle repetitive tasks, like quote requests, supplier evaluations, and approval processes. By setting up predefined channels, these workflows save time and reduce human error. Procurement teams can even create custom approval hierarchies based on factors like dollar amounts, risk levels, or project types.

Real-time collaboration makes communication seamless between internal teams and external suppliers. Updates, document revisions, and status changes are instantly visible to everyone involved, reducing miscommunications and helping projects stay on schedule.

Integration with existing systems connects sourcing platforms to ERP and CRM tools for a smooth flow of information. For instance, approved quotes can automatically generate purchase orders, supplier data can sync with accounting systems, and sales teams can track sourcing timelines that may affect deliveries. Platforms like QSTRAT take these benefits further by offering features tailored to global sourcing needs.

QSTRAT Features for Global Sourcing

Modern platforms like QSTRAT are a must for managing global supplier sourcing challenges. QSTRAT’s system has already handled more than $5 billion in RFQs across 22 countries, proving its ability to tackle complex international requirements.

Supplier performance management is made easy with dashboards that track key metrics in real time, such as on-time delivery rates, quality scores, and responsiveness. This helps procurement teams spot and address issues before they disrupt production.

Automated quoting systems simplify supplier communications. Suppliers receive standardized quote requests with all necessary details. The system tracks responses, sends reminders, and organizes results into easy-to-compare formats, speeding up evaluations.

Cost driver analysis goes beyond price comparisons by considering factors like shipping costs, duties, risks, and lead times. For instance, aerospace manufacturers can assess the cost implications of AS9100 certification, while automotive suppliers might analyze IATF 16949 compliance costs.

Decision support tools allow teams to evaluate suppliers by scoring them on criteria like cost, quality, and risk. This feature is especially valuable in industries where meeting regulatory standards is critical.

Data Security and Compliance

For manufacturers dealing with sensitive designs or working with defense contractors, security is non-negotiable. QSTRAT addresses this with a single-tenant cloud architecture that ensures data isolation and meets strict security standards.

"it is single tenant cloud both to ensure maximized customization capability and to meet the security requirements of defense contractors that are subject to rigid security requirements" – sourcinginnovation.com

This setup provides an added layer of protection compared to multi-tenant solutions, giving organizations confidence that their data is secure.

SOX compliance ensures financial data integrity by maintaining detailed audit trails. Every communication, decision, and data change is recorded with timestamps and user details, offering full accountability.

"SOX Compliance: complete audit trail including time, date and name stamp for every communication" – QSTRAT

Secure supplier interactions are another key feature. Suppliers can submit information via secure PDF forms, avoiding the need to log into sensitive portals – ideal for those with less advanced IT systems.

Lastly, compliance tracking helps manufacturers monitor regulatory requirements directly within the platform. By tracking risk factors, mandates, and insurance requirements, the system ensures that no details are missed. It also supports international compliance, allowing users to adapt to evolving trade regulations and country-specific standards.

sbb-itb-827f251

Best Practices and Risk Management in Global Sourcing

Once you’ve nailed down the process of evaluating and selecting suppliers, the next step is managing risks effectively. While global sourcing opens doors to exciting opportunities, it also comes with challenges that can disrupt operations if not handled carefully. Manufacturers who succeed in this space often rely on strong risk management frameworks to protect their supply chains while still benefiting from the cost and quality advantages of sourcing internationally.

Conducting Thorough Due Diligence

Financial stability assessments are a must. Start by reviewing audited financial statements from the past three years, focusing on cash flow trends, debt-to-equity ratios, and revenue patterns. This is especially important for suppliers in emerging markets, where financial reporting may vary. Declining revenues or rising debt levels can be red flags for future delivery issues.

Facility audits are another critical step. Visiting manufacturing sites gives you a firsthand look at operations – equipment conditions, workforce skills, and quality control processes. Take detailed notes and photos to document everything. Also, confirm that suppliers hold the necessary industry certifications.

Regulatory compliance verification helps shield your business from legal and reputational risks. Make sure suppliers have valid licenses, environmental permits, and any required industry certifications. For example, in China, you might need third-party auditors to check social compliance, while European suppliers should demonstrate GDPR compliance if they handle customer data.

Reference checks offer valuable insights into a supplier’s performance. Talk to at least three current customers and ask specific questions about delivery reliability, quality issues, and how the supplier resolves problems. Pay extra attention to feedback from customers with similar volume needs and technical requirements.

By conducting these assessments, you lay the groundwork for smoother communication and better risk management throughout the sourcing process.

Communication and Collaboration

Time zone management is key to keeping projects on track. For example, U.S. companies working with Asian suppliers can schedule calls between 6:00 AM and 9:00 AM Pacific Time to align with their suppliers’ workday.

Language barriers can lead to costly misunderstandings, particularly with technical details. Use visual aids like engineering drawings, photos, and videos to clarify your points, and avoid idioms or region-specific references. To ensure clarity, ask suppliers to restate their understanding of your requirements.

Documentation standards ensure everyone is on the same page. Use standardized templates for purchase orders, quality specifications, and delivery terms. When working internationally, include both metric and imperial measurements, use 24-hour time formats, and clearly specify time zones (e.g., "2:00 PM EST").

Cultural sensitivity can strengthen relationships and prevent miscommunication. For instance, in many Asian cultures, suppliers may avoid saying "no" directly. Instead, they might say, "it will be difficult" or "we will try our best." Learn to interpret these responses and ask follow-up questions to clarify their actual capabilities and timelines.

Risk Mitigation Methods

Supplier diversification is essential to avoid single points of failure. Always have at least two qualified suppliers for critical components, ideally in different regions. The 2011 tsunami in Japan was a wake-up call for manufacturers who relied too heavily on single-region sourcing.

Inventory buffering helps cushion against disruptions. For components from high-risk regions or suppliers with long lead times, increase safety stock levels. Use historical data to calculate buffer levels – critical items might need 90 days of inventory, while standard items could require just 30 days.

Contract protections can shift risks back to suppliers. Include force majeure clauses to handle unforeseen delays and penalty clauses to cover the costs of late deliveries. Also, require suppliers to carry business interruption insurance and list your company as an additional insured party.

Geopolitical monitoring keeps you ahead of trade disruptions. Subscribe to updates from the U.S. Trade Representative’s office and monitor tariff schedules for your product categories. Partnering with customs brokers can also help you navigate regulatory changes and trade disputes.

Here’s a quick look at common risks and how to address them:

| Risk Type | Mitigation Method | Implementation Timeline |

|---|---|---|

| Supplier bankruptcy | Dual sourcing + financial monitoring | 3-6 months |

| Quality failures | Incoming inspection + supplier audits | 1-2 months |

| Delivery delays | Safety stock + backup suppliers | 2-4 months |

| Currency fluctuation | Forward contracts + pricing adjustments | 1 month |

| Trade disputes | Geographic diversification + tariff planning | 6-12 months |

| Natural disasters | Multi-region sourcing + emergency protocols | 6-9 months |

Performance monitoring systems can act as an early warning system. Track metrics like on-time delivery rates, quality rejection percentages, and response times. Set up alerts for when performance dips below acceptable levels. Monthly scorecards can also help suppliers stay focused on improvement and give you data to guide sourcing decisions.

Emergency response planning ensures your team is ready to act fast during disruptions. Have backup contact lists and decision trees in place, and run tabletop exercises to practice these procedures. When real problems arise, your team will know exactly what to do.

These strategies tie directly into the broader discussion of leveraging technology to strengthen supplier relationships and manage risks effectively.

Compliance, Cost Efficiency, and Performance Optimization

Building on earlier discussions about risk management, let’s now focus on how compliance, cost efficiency, and supplier performance can align with your global sourcing strategy. By integrating these elements, you can create a supply chain that not only meets regulatory demands but also supports long-term business goals.

Compliance with Regulations

Navigating regulatory requirements is non-negotiable in global sourcing. Here’s how to stay on top of key compliance areas:

Import/export controls: Adhering to regulations like EAR and ITAR is critical. Noncompliance can lead to hefty fines. For example, exporting certain dual-use items, such as specific semiconductors, may require a license – even to allied nations. Always check product classifications on the Commerce Control List (CCL) and maintain detailed shipment records.

Quality standards compliance: Standards vary by industry and market. For instance, medical device manufacturers must ensure suppliers meet FDA 21 CFR Part 820 standards, while aerospace companies often require AS9100 certification. In Europe, products may need CE marking to access the market.

Supply chain transparency: Regulations like the Uyghur Forced Labor Prevention Act demand full visibility into your supply chain. Companies must trace materials back to their origins and confirm the absence of forced labor. This often involves supplier mapping and third-party audits, especially in high-risk regions.

Environmental and data protection regulations: Complex rules like the EU’s REACH and GDPR require careful attention. REACH mandates chemical safety data for certain substances, while GDPR governs data handling for European customers – even for suppliers outside the EU. Platforms like QSTRAT can simplify compliance by centralizing supplier certifications and flagging potential gaps.

Cost Optimization Methods

Balancing compliance with cost efficiency is a challenge, but these strategies can help:

Total cost of ownership (TCO) analysis: Look beyond unit prices to include transportation, duties, inspections, and inventory costs. This gives a clearer picture of overall expenses.

Currency hedging strategies: Protect against exchange rate volatility with tools like forward contracts or options. In unstable currency environments, negotiating prices in US dollars can shift risk back to the supplier.

Volume consolidation: Pooling purchases can secure lower rates and reduce administrative costs. However, weigh these benefits against potential increases in inventory costs or reduced supply chain flexibility.

Market benchmarking: Use real-time data to ensure supplier pricing aligns with industry norms. Tools like QSTRAT’s analytics can highlight discrepancies and provide leverage during negotiations.

Supplier development programs: Investing in supplier training and process improvements can enhance quality and efficiency, reducing defects and inspection costs over time.

Payment terms optimization: Negotiating extended payment periods or early payment discounts can improve cash flow and reduce overall costs.

Measuring Supplier Performance

Effective supplier management relies on robust performance measurement tools and practices:

Set clear KPIs: Define metrics like on-time delivery, quality, cost, and responsiveness to evaluate supplier performance objectively.

Scorecard systems: Combine multiple KPIs into a single performance rating. Weight metrics based on their importance – such as prioritizing delivery timeliness or quality consistency – to provide clear benchmarks for suppliers.

Performance trend analysis: Use data to spot gradual declines in performance. Identifying issues early can prevent larger problems down the line.

Supplier performance reviews: Regular reviews create a structured feedback loop. They clarify expectations, address upcoming needs, and set improvement goals.

Benchmarking against industry standards: Comparing supplier metrics to industry averages helps ensure competitiveness. It can also signal when a supplier change might be necessary.

Platforms like QSTRAT simplify these processes by offering centralized data collection and automated reporting. They also provide tools for trend analysis and decision support, helping you identify high-performing suppliers and areas for improvement.

Continuous improvement programs: Use performance data to drive actionable changes. Sharing insights with suppliers and setting collaborative goals can lead to ongoing enhancements. Suppliers who consistently exceed expectations may even earn preferred status and a larger share of future business.

Conclusion

Global supplier sourcing has shifted from being just a cost-saving tactic to becoming a key driver of growth, efficiency, and innovation. This guide has highlighted how manufacturers can successfully navigate the challenges of international sourcing while upholding quality, compliance, and performance standards.

One of the biggest changes in this space is the digital transformation of sourcing processes. Cloud-based tools like QSTRAT have reshaped global sourcing by centralizing supplier data, automating workflows, and offering real-time visibility into supply chains. These platforms effectively remove the obstacles of distance and time zones, making global sourcing much more streamlined and reliable.

To succeed in global sourcing, manufacturers need a systematic, digital-first approach that spans the entire process – from identifying suppliers to managing ongoing relationships. This ensures that sourcing decisions align with business goals and financial considerations.

At the same time, risk management and compliance have become critical priorities. With increasingly strict regulations, maintaining transparency and tracking certifications are essential. Adhering to standards like ITAR, FDA 21 CFR Part 820, and AS9100 is non-negotiable for fostering trust and maintaining partnerships. Digital platforms simplify this process by providing the documentation and audit trails needed for regulatory reviews, while also supporting cost-saving initiatives.

Speaking of costs, cost efficiency in global sourcing goes beyond just negotiating lower prices. Strategies like total cost of ownership analysis, currency hedging, and volume consolidation play a significant role in achieving long-term savings. However, the real advantage lies in using data-driven insights to make smarter decisions about supplier selection and performance.

Manufacturers who excel in today’s global market understand that technology is more than a tool – it’s a strategic asset. By leveraging cloud-based platforms, they not only improve efficiency but also gain insights that shape their long-term strategies. As supply chains grow more complex and interconnected, companies with robust digital infrastructures are better positioned to seize opportunities while managing risks effectively.

The formula for global sourcing success lies in the right balance of strategy, processes, and technology. Investing in comprehensive sourcing platforms delivers measurable benefits – stronger supplier relationships, reduced compliance risks, and smarter cost management that directly impacts profitability.

FAQs

What are the main advantages of using cloud-based platforms like QSTRAT for sourcing global suppliers?

Cloud-based platforms such as QSTRAT make global supplier sourcing more manageable and efficient. By offering a centralized system, they allow teams to oversee supply chain activities from virtually anywhere, leading to better coordination and improved transparency across international markets.

These tools also help simplify sourcing processes, enabling businesses to stay compliant with regulations while cutting expenses. With the integration of advanced analytics and AI, users can forecast demand, spot potential disruptions, and make smarter, data-backed decisions. The result? A more effective and streamlined supply chain.

What are the best ways to manage risks like supplier bankruptcy or delivery delays in global sourcing?

Managing risks in global supplier sourcing calls for a thoughtful and forward-thinking strategy. One key step is to spread your supplier network across various regions. This reduces dependence on a single location and helps safeguard your operations against disruptions like geopolitical conflicts or natural disasters.

Another critical measure is to create well-defined contracts. These should outline roles, responsibilities, and expectations clearly to avoid misunderstandings and minimize the risk of delivery setbacks. On top of that, using supply chain monitoring tools – such as software for tracking supplier performance and assessing risks – can help you spot potential problems early and take quick action to address them.

By integrating these methods, businesses can build a more resilient supply chain and keep their global sourcing processes running smoothly.

How can I ensure compliance with international regulations when sourcing from global suppliers?

To navigate global sourcing while staying compliant with international regulations, the first step is to fully grasp the legal landscape in the countries where your suppliers operate. This includes understanding laws tied to contracts, labor conditions, intellectual property, and even environmental guidelines.

Set up a detailed supplier code of conduct that clearly defines expectations for ethical labor practices, anti-corruption efforts, and environmental accountability. Conduct regular audits, especially in regions prone to higher risks, to ensure compliance and address any shortcomings. Using tools like risk monitoring software or traceability systems can provide real-time insights and help you stay on top of evolving regulations.

Building strong partnerships with your suppliers is equally important. Offer them training and resources to meet compliance requirements effectively. Maintaining open communication and continuous monitoring will go a long way in ensuring they adhere to international standards over the long haul.